Our blind flanges stand as versatile terminators in piping systems, providing a solid, no-bore solution for capping off lines with precision and reliability. Serving essential roles in fluid and air control, blind flanges are particularly valuable for creating secure terminations, facilitating future modifications, and rerouting media within a pipe assembly.

Designed to be machined for specific requirements, our blind flanges offer customization options such as threaded or welded reductions to accommodate various pipe sizes. We go beyond basic configurations, offering custom machining that includes NPT threads in the center and tailored bore holes for slip-on flanges without hubs.

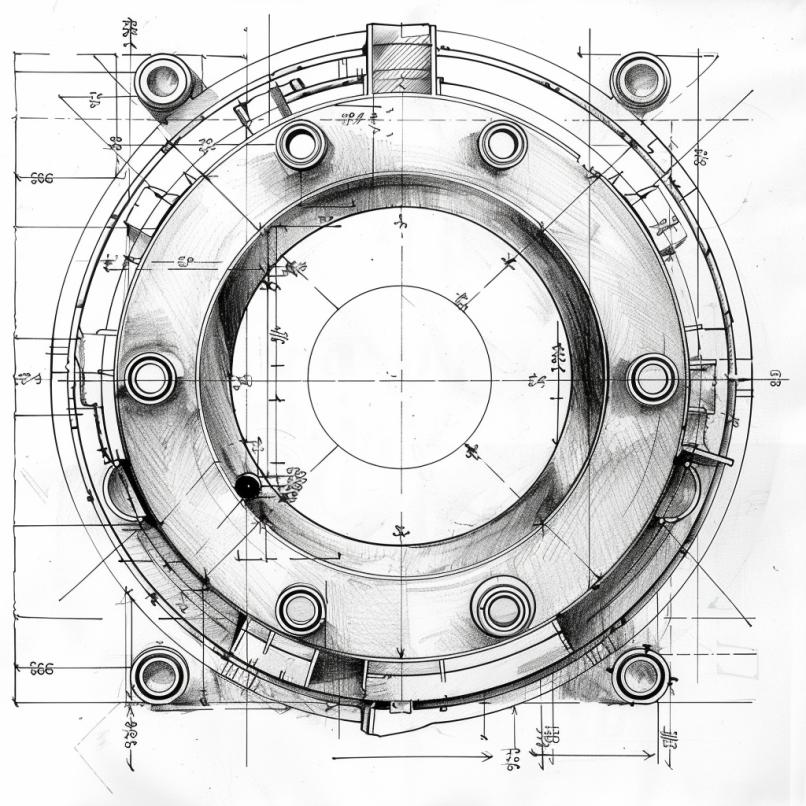

A blind flange, a solid steel cap without an interior diameter, provides a secure endpoint for piping systems. It's ideal for redirecting media flow and accommodating future modifications like valve installations, making it a versatile choice for various applications.

A blind flange, also known as a blanking flange, is a solid plate used to seal off the end of a piping system or pressure vessel opening. It does not have a bore and serves as a closed end to terminate a pipeline.

Blind flanges are typically manufactured from various materials such as carbon steel, stainless steel, alloy steel, duplex steel, and nickel alloys, depending on the application and the required corrosion resistance and strength.

Blind flanges are available in a wide range of sizes to suit different piping systems. Common sizes include 1/2", 3/4", 1", 1-1/2", 2", 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 24", and larger sizes as per customer requirements.

Blind flanges are designed to withstand various pressure ratings, such as Class 150, 300, 600, 900, 1500, and 2500, as per ASME B16.5 standards. The pressure rating determines the flange's thickness and the number and size of bolts required.

Blind flanges are typically manufactured in accordance with international standards such as ASME B16.5, ASME B16.47 Series A and B, API 605, and EN 1092-1, ensuring consistent dimensions, tolerances, and performance.

Yes, blind flanges can be customized to meet specific requirements, such as non-standard dimensions, unique materials, or additional features like weep holes for pressure gauges or tapered edges. Manufacturers can work with customers to design and produce custom blind flanges.

Blind flanges are typically bolted to a mating flange using studs or bolts and nuts. A gasket is placed between the flanges to create a tight seal. The bolts are tightened in a star or crisscross pattern to the specified torque value to ensure even compression of the gasket.

Blind flanges provide a reliable and cost-effective solution for sealing off piping systems or openings. They are easy to install and remove, allowing for quick access to the system for maintenance or modifications. Blind flanges also offer excellent pressure containment and are suitable for a wide range of applications and industries.

Yes, blind flanges can be machined per customer specifications to have a raised face (RF), flat face (FF), Nubin or Ring Type Joint (RTJ) depending on application.

No, typically, blinds are not required to have an Inner Diameter(ID) called out unless customer is needing a hole for a nozzle or special machining.

The information needed to quote a blind flange are quantity, size, pound rating, Material grade and specifications or restrictions.

Need blind flanges with quality you can rely on? Our expert team is here and ready to discuss your project details with you. Let's get started.

Carlson Company is part of Riverbend Industries, an owner-investor supporting the U.S. manufacturing sector and related industries. Riverbend seeks to support its companies’ unique cultures while fostering an environment of entrepreneurship.