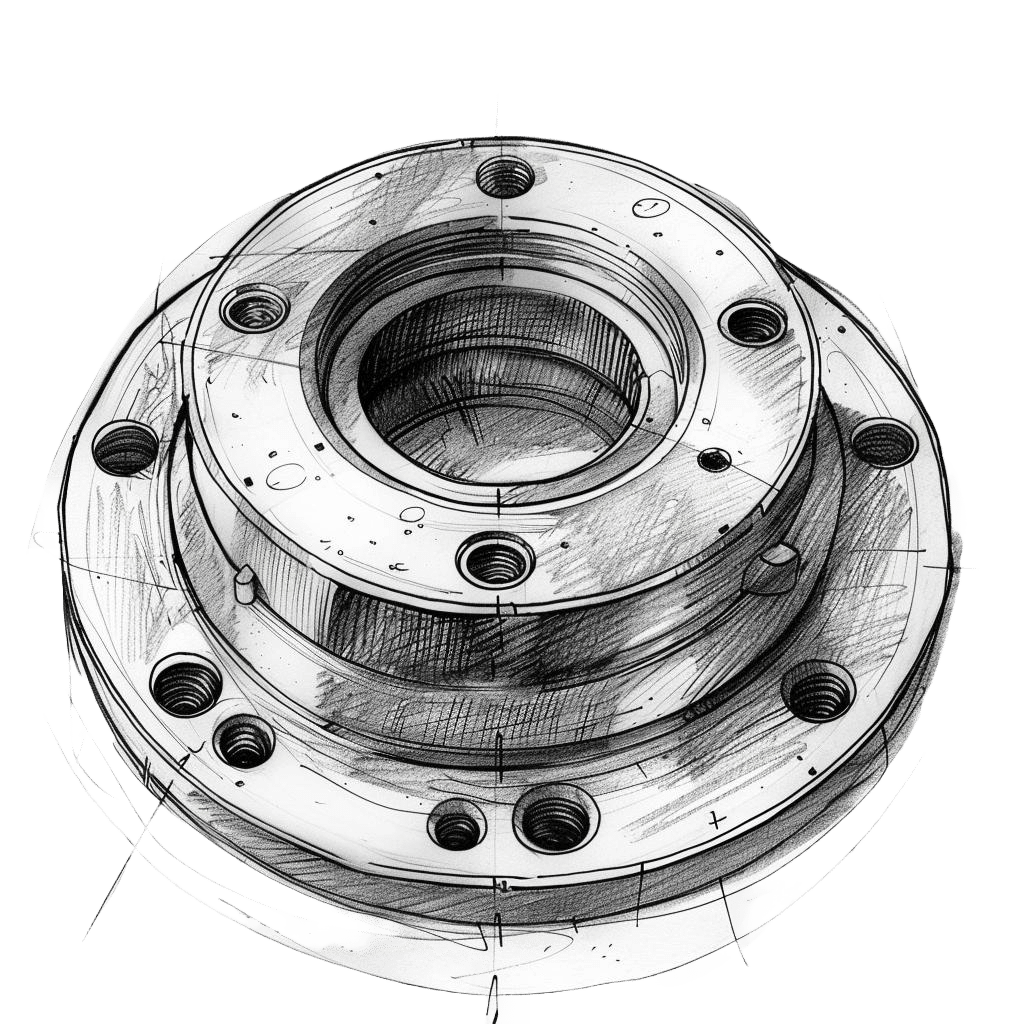

Our nozzle flanges are intricately designed to seamlessly integrate into pressure vessels and tanks, providing optimal functionality and durability. Crafted with unrivaled attention to detail, our nozzles stand a testament to our commitment to precision and excellence. We go beyond conventional nozzles, providing a variety of connections with varying wall thicknesses.

These nozzle flanges, often referred to as "long neck" flanges, eliminate the need for standard weld neck and pipe weld combinations. With a straight thru bore and adjustable lengths, these flanges offer versatility to match specific requirements across various industries. The base of the neck connecting to the flange is carefully radiused, reinforcing a sturdy, one-piece construction.

Nozzle flanges are crucial components in industrial piping systems, serving as connectors between pipes and various equipment such as vessels or tanks. These flanges provide a secure and leak-resistant connection, facilitating efficient fluid transfer and ensuring the integrity of the overall system.

Nozzles are components that provide a means for fluids or gases to enter or exit a vessel, tank, or pipe. They are designed to control the flow, direction, and velocity of the fluid or gas.

Nozzles are widely used in various industries, such as oil and gas, chemical processing, food processing, power generation, and industrial manufacturing.

We offer a wide range of nozzle types, including threaded nozzles, socket weld nozzles, butt weld nozzles, and flanged nozzles, to suit different application requirements.

We manufacture nozzles in a variety of materials, such as carbon steel, stainless steel, duplex steel, and other alloys, to meet specific application needs and environmental conditions.

Yes, as a custom specialty flange manufacturer, we can produce nozzles in custom sizes, lengths, and configurations to fit your specific vessel, tank, or piping requirements.

Our nozzles are manufactured in accordance with international standards, such as ASME B16.5, ASME B16.11, ASME B16.25, and API 605, ensuring quality, reliability, and compatibility with industry requirements.

We offer nozzles in a wide range of pressure ratings, from ASME Class 150 to Class 2500, and API 2000 to 10000, to accommodate various application needs and process conditions.

To select the appropriate size and pressure rating for your nozzle, consider factors such as the vessel or pipe size, operating pressure, temperature, and the nature of the fluid or gas being transported.

Yes, we can customize the end connections of nozzles to suit your specific application requirements, such as threaded, socket weld, butt weld, or flanged connections.

We offer various surface finishes for nozzles, such as machined, polished, or coated, depending on your specific requirements and the application environment.

Yes, we can apply custom coatings to nozzles, such as anti-corrosion, high-temperature, or erosion-resistant coatings, to enhance their performance and durability in demanding environments.

Lead times for custom nozzles may vary depending on the complexity of the design, material availability, and production schedule. Please contact our sales team for an accurate lead time estimate for your project.

Yes, we provide NDT services, such as radiography, ultrasonic testing, and magnetic particle inspection, to ensure the quality and integrity of our nozzles.

Yes, we can provide nozzles with special markings, tags, or barcodes to meet your traceability and identification requirements, facilitating easy tracking and inventory management.

We supply comprehensive documentation with our nozzles, including material test reports (MTRs), inspection reports, and certificates of conformity, to ensure compliance with your specifications and international standards.

Need nozzle flanges you can rely on? Our team is here to discuss your project details with you. Let's get started.

Carlson Company is part of Riverbend Industries, an owner-investor supporting the U.S. manufacturing sector and related industries. Riverbend seeks to support its companies’ unique cultures while fostering an environment of entrepreneurship.