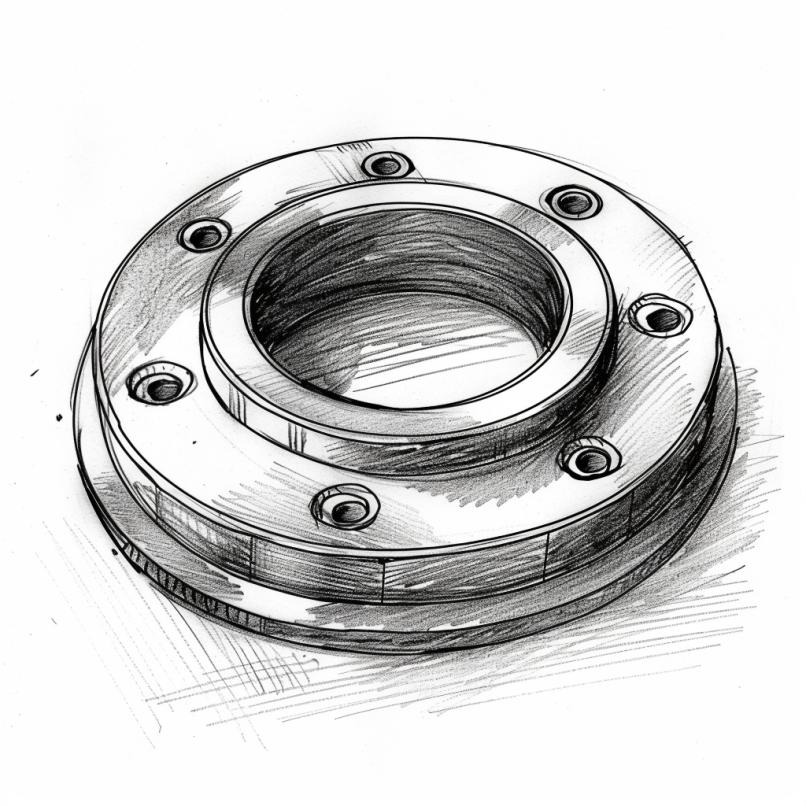

Our studding outlet flanges stand out for their material versatility, with the most common being A/SA-105N. However, we offer a comprehensive range, including various stainless and alloy materials to meet the diverse needs of your applications. Adhering to ASME standards, we meticulously follow drilling and tapping specifications, with thread depth considerations for specific design temperatures and stress conditions.

Ensuring structural integrity, the standard thickness adheres to ASME Section VIII Division I Paragraph UG-43(d) for thread engagement and I.D. mount. We also offer contoured connections at an additional cost, ensuring a seamless fit for shells, heads, pipes, or vessels.

Our studding outlet flanges are highly versatile, featuring materials like A/SA-105N, stainless, and alloys to suit diverse applications. Adhering to ASME standards, we prioritize precision in drilling, tapping, and thread depth for optimal performance in different industrial conditions.

A Studding Outlet Flange is a type of flange designed to provide a connection point for piping or equipment, featuring threaded studs or bolts around the circumference for secure attachment.

Studding Outlet Flanges are widely used in various industries, including oil and gas, industrial manufacturing, food processing, and power generation.

We offer Studding Outlet Flanges in a range of materials, such as carbon steel, stainless steel, duplex steel, and other alloys, to suit different application requirements.

Yes, as a custom specialty flange manufacturer, we can produce Studding Outlet Flanges in custom sizes to fit your specific piping or equipment dimensions.

Our Studding Outlet Flanges are manufactured in accordance with international standards, such as ASME B16.5, ASME B16.47, and API 605, ensuring quality and compatibility.

We offer Studding Outlet Flanges in a wide range of pressure ratings, from ASME Class 150 to Class 2500, and API 2000 to 10000, to suit various application needs.

Yes, we can customize the drilling pattern on Studding Outlet Flanges to match your specific requirements, ensuring proper alignment and fit with your piping or equipment.

The maximum temperature rating for our Studding Outlet Flanges depends on the material grade and pressure class. Please consult with our sales team for specific temperature ratings.

To select the appropriate size and pressure rating, consider factors such as pipe size, operating pressure, temperature, and the nature of the fluid being transported.

We offer various surface finishes for Studding Outlet Flanges, such as machined, painted, or galvanized, depending on your specific requirements and the application environment.

Yes, we can apply custom coatings to Studding Outlet Flanges, such as anti-corrosion or high-temperature coatings, to enhance their performance and durability in specific environments.

Lead times for custom Studding Outlet Flanges may vary depending on the complexity of the design, material availability, and production schedule. Please contact our sales team for an accurate lead time estimate for your project.

Yes, we provide NDT services, such as radiography, ultrasonic testing, and magnetic particle inspection, to ensure the quality and integrity of our Studding Outlet Flanges.

Yes, we can provide Studding Outlet Flanges with special markings, tags, or barcodes to meet your traceability and identification requirements.

We supply comprehensive documentation with our Studding Outlet Flanges, including material test reports (MTRs), inspection reports, and certificates of conformity, to ensure compliance with your specifications and international standards.

Looking for high-quality studding outlet flanges? Our team of experts is here and here to discuss your project details with you. Let's get started.

Carlson Company is part of Riverbend Industries, an owner-investor supporting the U.S. manufacturing sector and related industries. Riverbend seeks to support its companies’ unique cultures while fostering an environment of entrepreneurship.